Polymer injective molding is a highly efficient and flexible manufacturing process that has become a cornerstone in the fabrication of plastic components. It is widely used across various sectors, from vehicle to retail products, due to its capacity to produce intricate shapes with precision and consistency. For beginners looking to understand the realm of polymeric injective forming services, it is crucial to grasp the fundamental principles, methodologies, and the diverse applications of this process.

In this guide, we'll explore the details of polymeric injective molding services, including how they function, the substances used, and the advantages they offer. Whether you are a business owner considering your initial manufacturing run or a hobbyist interested in DIY endeavors, understanding the fundamentals of plastic injective molding will arm you with the insight you require to make informed choices and drive the success of your projects.

Comprehending Plastic Injection Molding

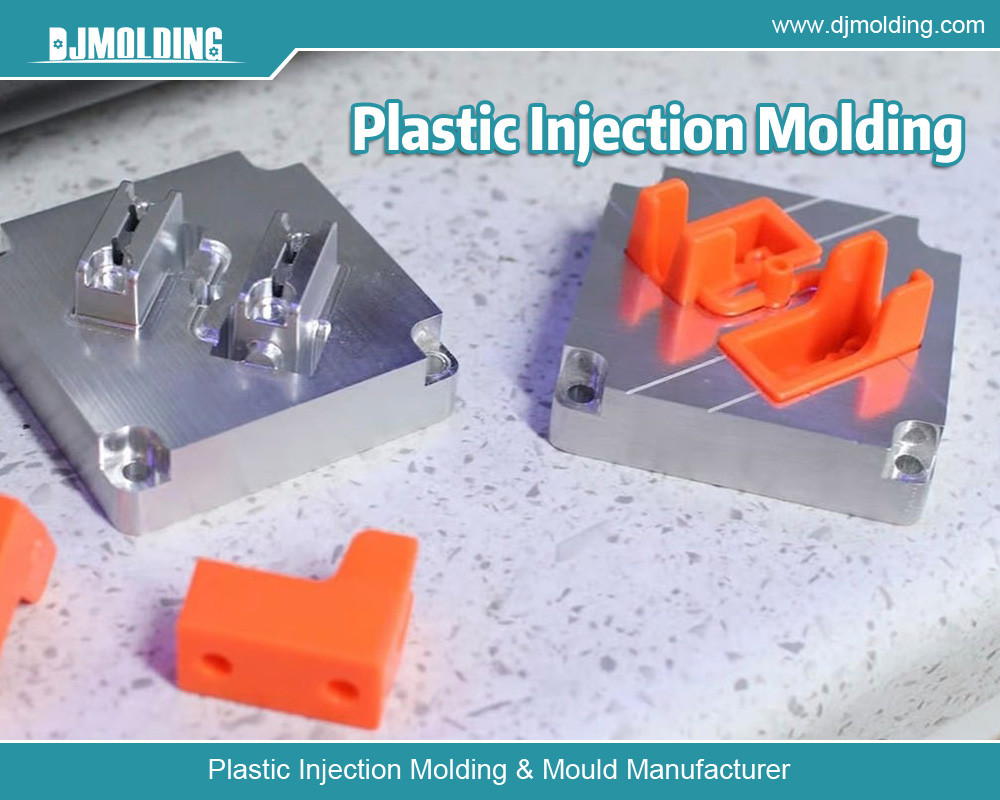

Injection molding of plastics is a manufacturing method used to manufacture plastic products by injecting molten plastic into a mold. This process is very effective and capable of producing complex shapes with high precision, making it a popular choice for a variety of applications. The process starts with the choice of unprocessed plastic materials, which are heated until they become liquid and then forced under high pressure into a specially designed mold. Once the plastic solidifies and solidifies, the mold is removed, and the finished product is ejected.

One of the main advantages of plastic injection molding is its ability to scale. It is perfect for both limited production runs and large-volume manufacturing. Because of the high repeatability in the injection molding process, businesses can produce many thousands or even millions of identical parts with little waste. This efficiency not only reduces the cost per unit but also enables for a faster production cycle, helping companies meet strict timelines and demand fluctuations.

Moreover, plastic injection molding offers a large variety of material options, including thermoplastics and thermosetting plastics, each with unique properties suited for different applications. This versatility enables manufacturers to create products that are durable, lightweight, and capable of withstanding various environmental conditions. As industries continue to evolve, the role of plastic injection molding services becomes more and more important, providing innovative solutions to meet contemporary manufacturing needs.

Main Perks of Using Molding Solutions

One of the main advantages of employing plastic injection molding service s is the speed and rapidity of production. This production process allows for the rapid creation of complex parts in large quantities, making it perfect for manufacturers looking to scale their production. The high-speed cycles of injection molding mean that manufacturers can produce many of identical pieces in a brief period, reducing delivery times and meeting market demands more efficiently.

Another major plus is the versatility that injection molding offers. With the potential to work with a variety of thermoplastic materials, injection molding solutions can cater to multiple industries, including automotive, consumer goods, and medical devices. This versatility enables manufacturers to create a broad range of products with different shapes, sizes, and material properties, all while maintaining elevated levels of accuracy.

Additionally, plastic injection molding services provide financial savings in the long run. Although the upfront setup costs may be more elevated compared to other manufacturing methods, the potential to produce massive numbers with little waste significantly lowers the total cost per unit. This is particularly advantageous for businesses that require substantial quantities of parts, as it allows them to achieve higher margins while ensuring product quality and reliability.

Selecting the Ideal Molding Provider

Selecting the ideal injection molding partner is crucial for the success of your initiative. It is essential to analyze the capabilities and competencies of prospective partners. Look for companies with a verified track record in the industry, as their expertise can significantly impact the quality and efficiency of the final outputs. Additionally, take into account their technical expertise and the variety of services they offer, which may consist of design assistance, material selection, and prototype development.

Communication is another vital factor when selecting an injection molding provider. Creating a transparent line of dialogue can improve the production process and resolve any issues that may occur. A responsive partner who is ready to collaborate closely and provide updates on status can make a significant impact. Be sure to ask about their approach to managing projects and how they address timelines, modifications, and surprises.

Lastly, assess the economic aspects of the collaboration. While cost should not be the sole determinant, grasping pricing structures and payment terms is important. Request comprehensive quotes and assess the value offered in contrast to the prices. A partner who delivers transparency and demonstrates their commitment to quality might warrant a elevated fee. By thoroughly vetting your choices, you can find a dependable molding service that suits your objectives and budget.